Always at the righttemperature.

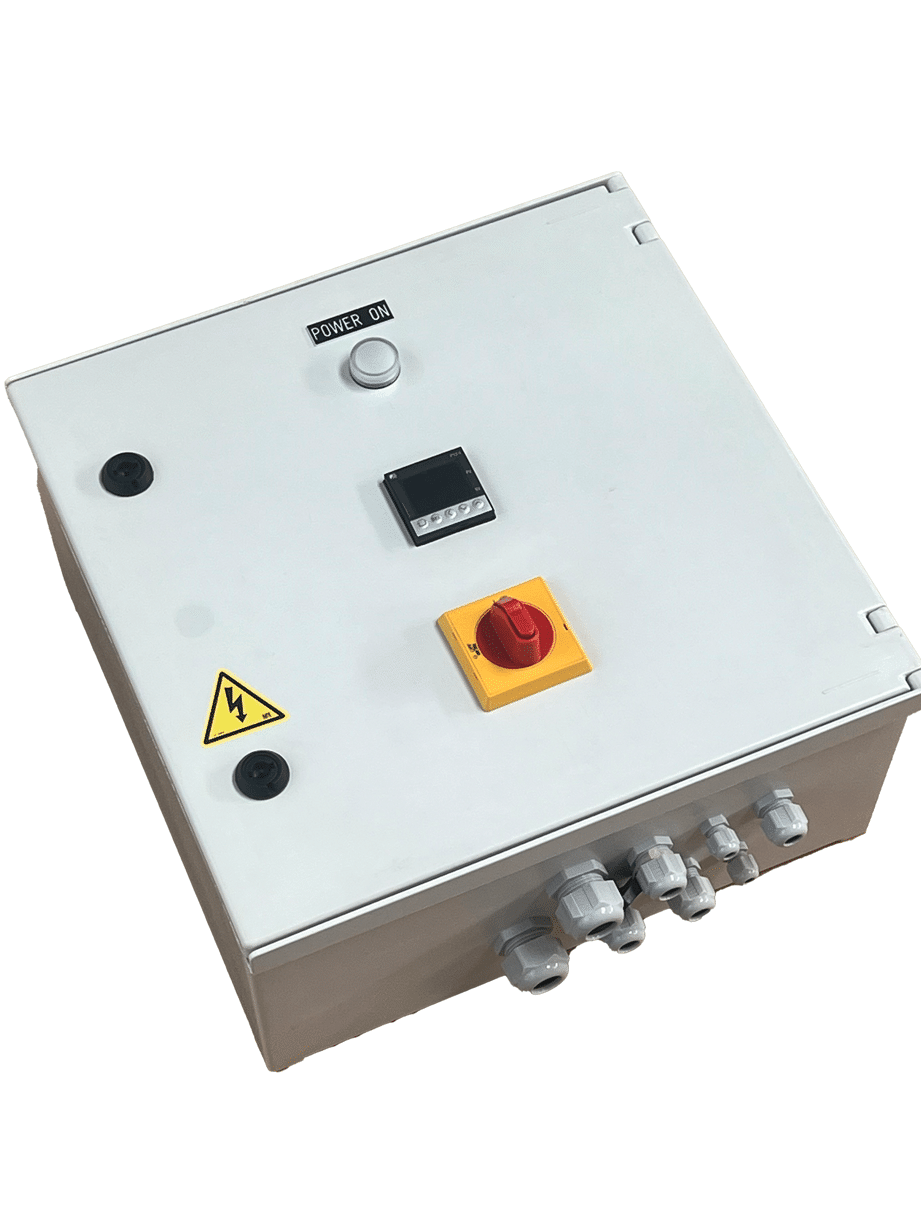

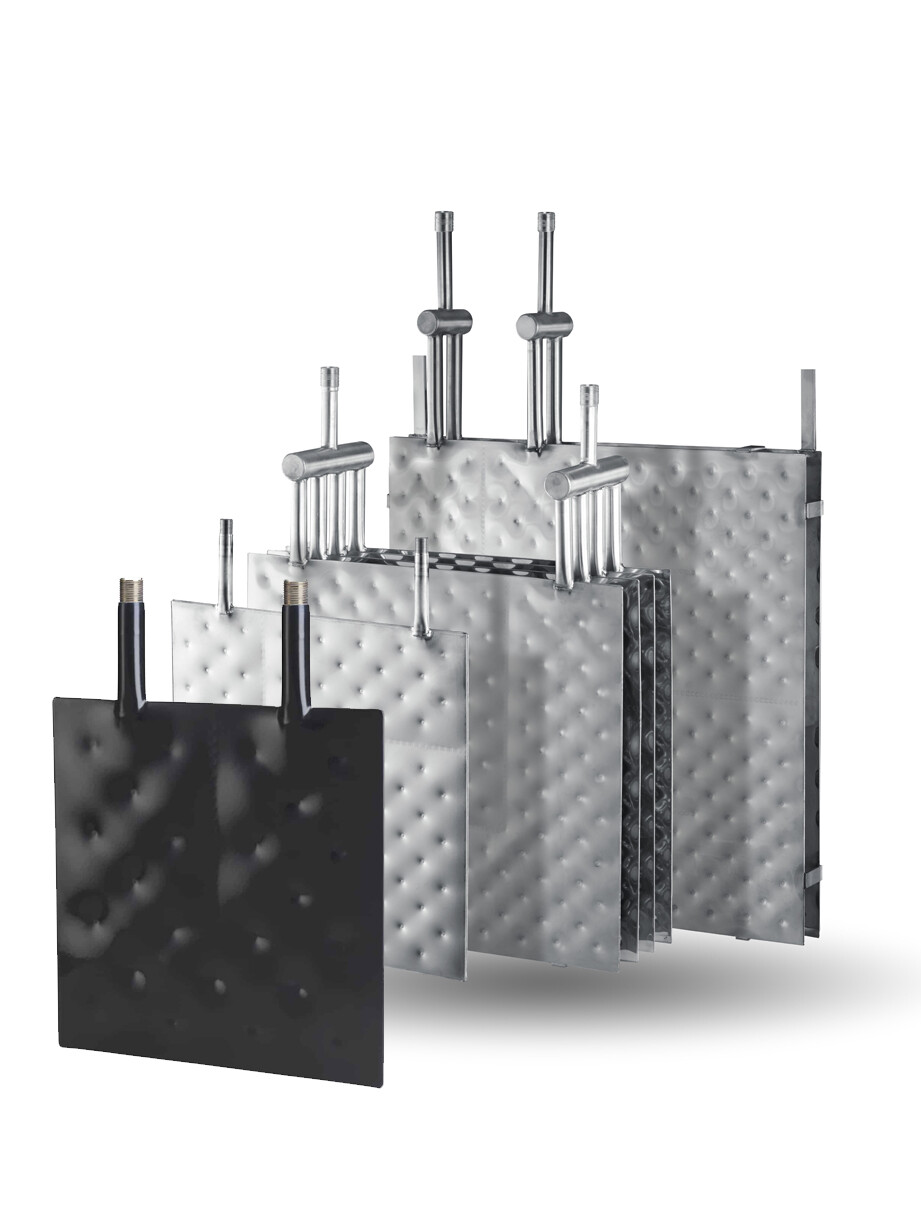

Galvatek, a French manufacturer of polymer industrial immersion heaters for corrosive liquids and temperature probes, specializing in industrial electrothermics

OUR MISSION:To offer you our expertise in the control and monitoring of liquids, chemicals and heating systems.

Partner your industrialchallenges.

Surface treatment, chemicals, pharmaceuticals or food processing: our electrothermal solutions can be adapted to the specific needs of each industry.

OUR MISSION:To provide a precise, tailor-made technical response to thermal control issues in every sector of activity.

Expertise closeat hand.

Thanks to its extensive sales network, Galvatek provides local support and optimum responsiveness throughout France and abroad.

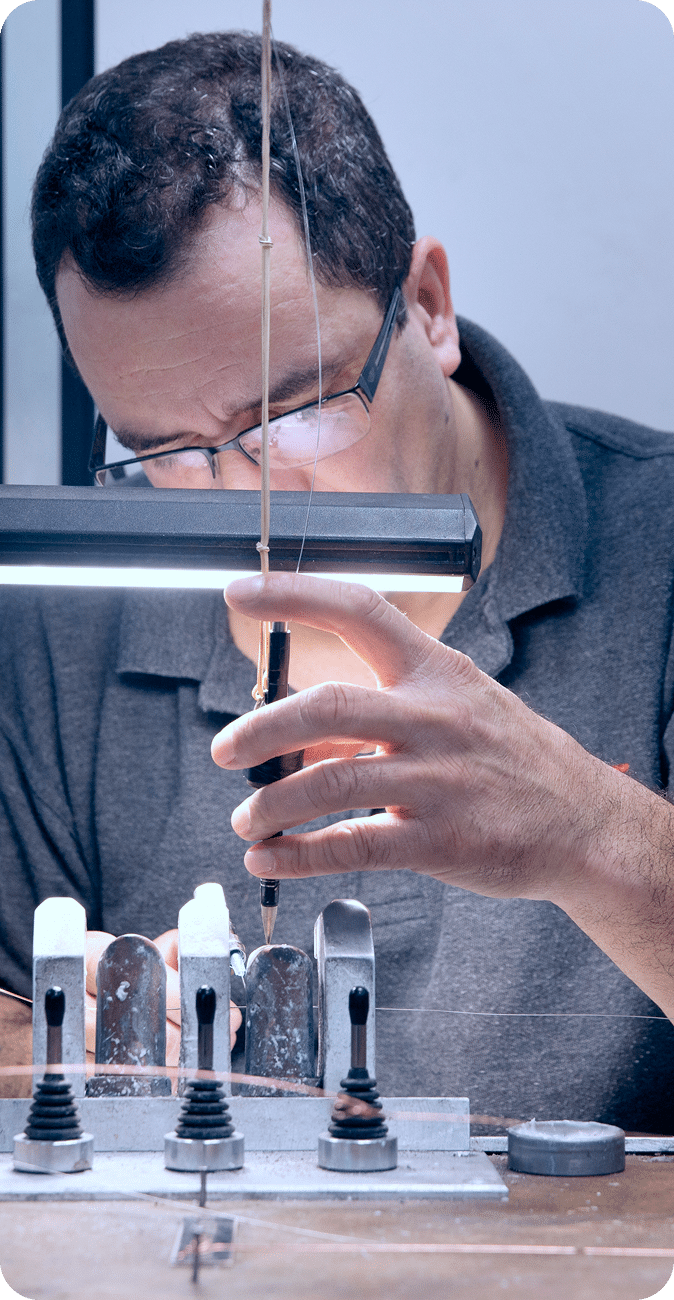

OUR MISSION:To advise you on a daily basis and support you in the installation and monitoring of your thermal equipment with our experts in the field.

Do you have a requirement?

We have the product to meet it.

Calculate the Power for your Heating and Cooling System

Based on your requested specifications, we analyze your data to provide the optimal technical solution within 48 hours.

- 100% Tailored Technical Proposal

- Expert Recommendations

- Confidentiality Guaranteed

We serve all industries

Our electrothermal solutions adapt to the most hostile environments. With our mastery of polymers, our dedicated equipment meets the specific requirements of every industry.

Technical Information

The safety and performance of your installations depend on a number of key points. We invite you to consult our technical recommendations and tables below, and remain at your disposal should you have any questions.

The chemicals used in the composition of treatment liquids impose the most varied requirements in terms of chemical resistance on the materials we use.

The choice of material must also take into consideration other physical properties such as the risk of scaling, thermal limits, or the maximum permissible surface power. The advantages and disadvantages, as well as the resistance tables, are intended to facilitate your choice. However, we remain at your disposal to guide you.

When installing immersion heaters at the tank rim, it is important that the orange electrical connection sleeve (or the BC or LC terminal boxes) is not immersed in the treatment liquid or exposed to vapors. Direct exposure to steam must be avoided by appropriate installation measures (e.g., a mounting flange or support).

Treatment liquids that can cause deposits or scaling on heated surfaces (e.g., potassium permanganate or phosphate baths) must be heated with a low surface load of the immersion tube, up to a maximum of 2 W/cm2.

Information on the resistance of different materials is provided for guidance only and only concerns aqueous solutions ranging from 0 °C to 100 °C. These indications are based on the chemical composition and properties of chemicals frequently used for surface treatment.

We disclaim all responsibility for the accuracy of the information provided, as many factors under the user’s control can significantly influence and modify the resistance of the indicated materials. We only assume a guarantee in cases where we confirm the material resistance in writing, based on your precise description of the main parameters.

This list does not claim to be exhaustive and does not cover all treatment liquids used in the surface treatment industry.

International coverage.

Galvatek immersion heaters and probes are exported worldwide. Rely on our network to secure your processes and contact our sales teams or agents for your projects.

Please contact us.

Contact our sales and technical teams and discuss your specific needs with our experts.

By phone: +33 1 30 93 07 57

By email: info@galvatek.fr